Economic Planter Monitoring

System Features

• Photosensored seed monitoring up to 8 rows

• Total hectare count

• Automatic system diagnostic

• Audible and visual blockage alarm

• 6 selectable thresholds for missing seed alarms

SEED ROWS MONITORING

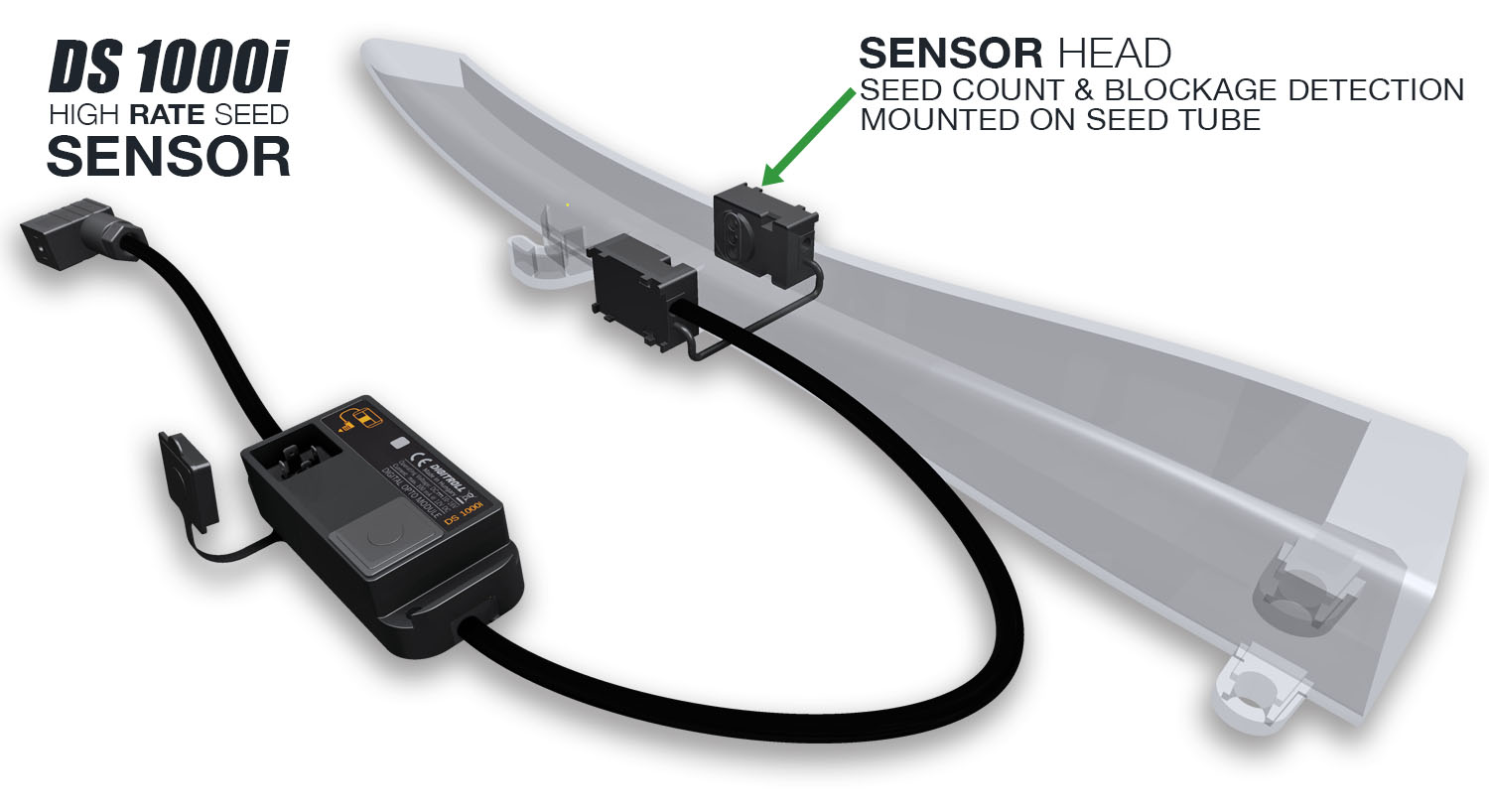

High Rate Seed Sensor – DS1000i

Mounted on Seed Tube

The DS1000i seed sensor is made to count dropping seeds on precision planters. 3-channel, high rate optical sensors, fine-tuned by seed shape and seed size settings, enable reliable detection of double/triple seed drops or skips. Each optomodule possess an intelligent processor unit run by microcontroller. Linear connection and interchangeable sensor sequence make installation easy in short time.

Sensor Features

• Seed count, seed-flow/blockage detection

• Detection and display of dust accumulation on seed sensor or blockage (DDC)*

• For planters 1-8 rows

• Mounted on seed tube

• Accurate seed detection with 3 infras

High Rate Seed Sensor – DS2000i

Mounted in the Coulter or under Seed Disk

The DS1000i seed sensor is made to count dropping seeds on precision planters. 3-channel, high rate optical sensors, fine-tuned by seed shape and seed size settings, enable reliable detection of double/triple seed drops or skips. Each optomodule possess an intelligent processor unit run by microcontroller. Linear connection and interchangeable sensor sequence make installation easy in short time.

Sensor Features

• Seed count, seed-flow/blockage detection

• Detection and display of dust accumulation on seed sensor or blockage (DDC)*

• For planters 1-8 rows

• Mounted in the coulter or under seed disk

• Accurate seed detection with 3 infras

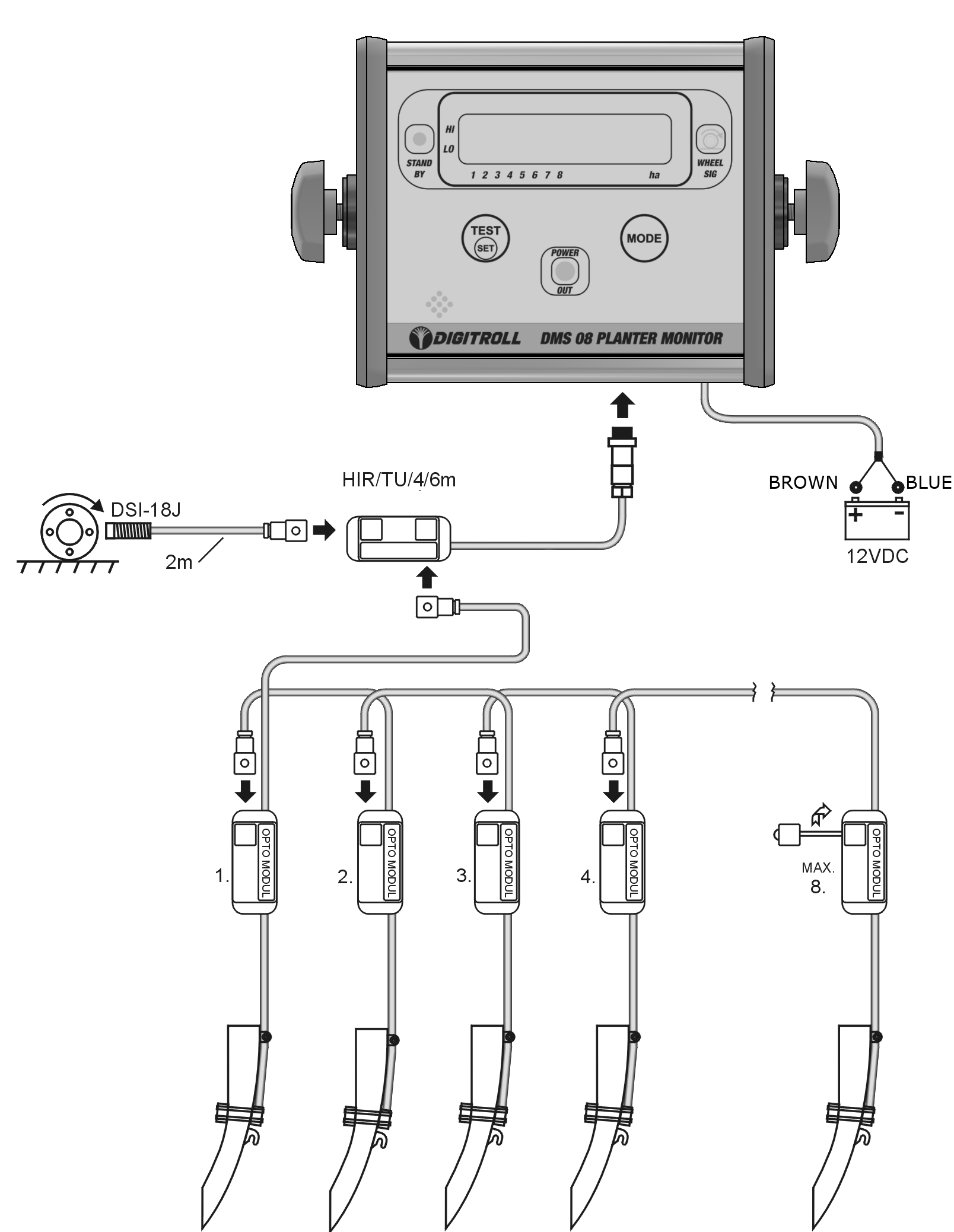

Monitor: DMS 08 LCD

Seed Sensors: DS 1000i / DS 2000i

Speed Module: DA 02i (wheel signal receiver)

• Display: High contrast alphanumeric LCD display

• Resolution: 1×16 characters

• Backlighting: LED backlight

• Quick Keys: 1 quick key for quick diagnostics

• Microprocessor: Microchip

• Operating Voltage: 12 VDC

• Diagnostic LEDs: 3 LEDs for quick diagnostics

• Operating Temperature: -20 .. +70 °C

• Storage Temperature: -30 .. +80 °C

• Protections: Overcurrent and polarity reversal protection

• Communication Port: String System Port

• Adjustable Horn Volume: Yes

• Standby Mode: Yes

• Dimensions (W x H x D): 155 x 103 x 34 mm

• Sensor Type: Photocell

• Seed Sensors: DS 1000i / DS 2000i

• Minimum Detectable Object size*: 1-2 mm

• Maximum Speed of Detectable Objects: cca.15m/s

• Optical Detection Elements: 3-pair

• Detection proccess: Digital Signal Procession

• DDC – Automatic Dust Compensation**

• Cleaning Alarm: Automatic – send alerts if the sensor optics surface dust is too high**

**Sensor cleaning is rarely due, thanks to Dust Detection & Compensation (DDC) function, so the operator can seed large areas without cleaning the sensors, allowing him to get the most out of the short seeding time at optimum conditions. The cleaning alarm is an unmatched solution to determine sensor dust level, then Dust Compensation, relying on dust test information, automatically compensate the sensibility. High sensitivity of blockage detection will be maintained by this solution. This solution is a Patented Technology by Digitroll.

Typical Applications & Benefits

• 4-8 row planters

• Small and simple planters

• Simple usage